Key Advantages and Considerations of Implementing Plastic Extrusion in Your Tasks

Recognizing the Essentials of Plastic Extrusion

Plastic extrusion, a staple in the manufacturing sector, is a procedure that involves melting raw plastic product and reshaping it right into a constant account. The elegance of plastic extrusion lies in its versatility. The option of plastic and the design of the die determine the item's qualities.

The Economic Benefit of Plastic Extrusion

The economic benefit of plastic extrusion exists primarily in 2 areas: economical product production and helpful production rates. With plastic extrusion, companies can generate high volumes of product at a reduced cost contrasted to other techniques. In addition, the process flaunts an impressive production rate, considerably lowering time and further boosting its financial practicality.

Cost-Effective Material Production

A substantial benefit of plastic extrusion is its impressive cost-effectiveness. Furthermore, the extrusion procedure allows for a high degree of accuracy in forming the plastic, reducing the demand for pricey post-production modifications or adjustments. All these factors make plastic extrusion a highly affordable selection for lots of projects, offering an eye-catching equilibrium in between cost and efficiency.

Beneficial Production Speeds

While keeping the cost-effectiveness of the materials, one more notable advantage of plastic extrusion depends on its quick production rates. This efficiency in the manufacturing procedure is credited to the constant nature of the extrusion procedure, enabling high-volume production in a reasonably short time span. The rate of manufacturing directly correlates to a reduction in labor prices and an increase in outcome, therefore enhancing the overall financial viability of the process. Moreover, the busy manufacturing does not compromise the high quality of the last item, making sure reputable and regular results. This combination of cost-effectiveness, speed, and top quality highlights the considerable economic advantage of executing plastic extrusion in different jobs.

Versatility and Modification: The Toughness of Plastic Extrusion

One of the popular strengths of plastic extrusion hinges on its adaptability and personalization capacity. These qualities unlock to unrestricted design opportunities, offering producers the ability to customize products to specific demands. This increased degree of personalization not only boosts product functionality however also significantly improves item originality.

Unlimited Design Opportunities

Plastic extrusion radiates in its ability to supply almost infinite style opportunities. This technique provides flexibility to create elaborate accounts and complex shapes, a task difficult to attain with other construction strategies. Owing to the fluid nature of liquified plastic, the process is versatile sufficient to yield a diverse array of dimensions, sizes, and kinds. The plastic can be manipulated to match distinct requirements, allowing for the production of personalized geometries and conference specific client needs. Plastic extrusion can take care you can try these out of a variety of plastic types, broadening its application extent. This versatile technique, consequently, offers a large range of markets from construction to automobile, product packaging to electronic devices, and past. With plastic extrusion, the design possibilities are basically endless.

Boosting Item Originality

The convenience of plastic extrusion can greatly boost item originality. This More hints procedure enables designers to try out various shapes, sizes, and shades, providing the liberty to develop special products that stand out in the market. It is this customization that offers a distinctive identification to every product, identifying it from its rivals.

In addition to its visual advantages, the customizability of plastic extrusion also supplies practical advantages. Hence, plastic extrusion not just enhances product originality but additionally its utility and marketability.

Layout Limitations in Plastic Extrusion: What You Need to Know

Just how can develop restrictions possibly influence the process of plastic extrusion? While plastic extrusion is flexible, design restrictions can curtail its advantages. Recognizing these constraints is important for efficient execution of plastic extrusion in your projects.

Examining the Ecological Influence of Plastic Extrusion

While understanding layout restrictions is a substantial element of plastic extrusion, it is just as crucial to consider its ecological ramifications. The procedure of plastic extrusion involves melting plastic products, possibly releasing hazardous gases right into the environment. Making use of recycled plastic products in the extrusion process can minimize ecological impact.

Situation Research: Effective Projects Using Plastic Extrusion

Success stories in the field of plastic extrusion are plentiful, showing both the convenience and efficiency of this production process. One remarkable example is the creation of PVC pipelines utilized in modern-day pipes. This procedure involves melting plastic and forming it into a continuous tube, providing significant expense and toughness benefits. An additional effective situation is the production visit the website of plastic movie for packaging and agriculture. Via extrusion, manufacturers can generate very personalized, slim, and durable films. Automotive markets also benefit, using extruded plastic for parts like trim or seals, boosting vehicle long life. These circumstances highlight plastic extrusion's essential function in different industries, testifying to its flexibility, cost-effectiveness, and dependable output.

Final thought

In final thought, plastic extrusion supplies a effective and affordable technique for producing complicated shapes with marginal waste. Including plastic extrusion right into projects can lead to successful results, as shown by numerous situation researches.

Plastic extrusion, a staple in the production industry, is a process that includes melting raw plastic product and improving it into a constant account. Plastic extrusion can take care of a variety of plastic kinds, increasing its application scope.Just how can design restrictions potentially influence the procedure of plastic extrusion? The procedure of plastic extrusion entails melting plastic materials, potentially launching damaging gases right into the setting. Making use of recycled plastic products in the extrusion process can decrease environmental impact.

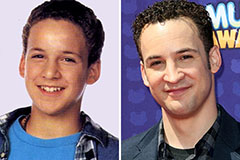

Ben Savage Then & Now!

Ben Savage Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!